Numerical modeling of combustion processes in porous media for efficient energy use

Recent advancements in numerical modeling at Tomsk Scientific Center SB RAS have led to the development of highly efficient Ni–Al-based intermetallic porous burners. These burners are fabricated using combustion synthesis technology (SHS), and both computational and experimental results suggest their performance is significantly superior to that of traditional ceramic burners. Specifically, the SHS-produced burners demonstrate efficiencies 2.5 to 5 times greater than that of ceramic ones. Moreover, the ability to control combustion processes over a wide range of operational parameters – such as pore size and geometry – was successfully demonstrated. The findings of this research have been published in prestigious journals, including Combustion Science and Technology and the International Journal of Hydrogen Energy .

– The demand for efficient, environmentally friendly energy systems is growing rapidly, especially as industries look for solutions that conserve resources and utilize alternative fuels, – explains Igor Yakovlev, Senior Researcher at the Technological Combustion Laboratory of TSC SB RAS and Candidate of Physical and Mathematical Sciences. – In this context, the ability to control the combustion process is one of the most pressing challenges in our field. Porous burners offer a promising solution, enabling the combustion of various fuels with high efficiency while minimizing harmful emissions.

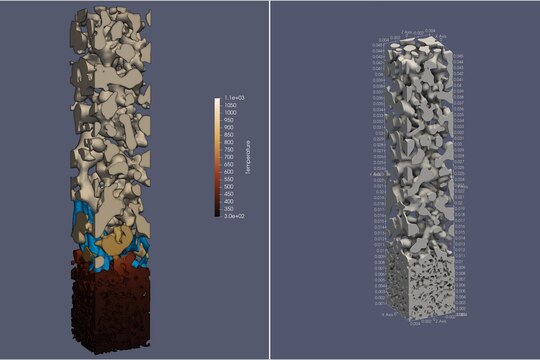

The difficulty arises from the fact that the nature of experimenting with this type of burners renders the observing (let alone controlling) of physical processes occurring inside the pores during combustion impossible. To address this, the team turned to advanced numerical modeling techniques. Whereas earlier models considered the impact of porous media geometry on combustion based on averaged, semi-empirical parameters, the computational power available now allows for the pore structures to be accounted for explicitly. This is achieved by employing X-ray computed tomography (CT) to scan the porous media samples directly, providing a more detailed and accurate representation of their structure.

– By digitizing these structures, we can construct highly accurate numerical models that reveal the entire pore architecture. These models allow us to track gas flow through the porous channels, chemical reactions, and heat transfer between combustion products and the porous medium. This new approach provides a deeper understanding of the underlying physical processes within these porous structures, – Yakovlev notes.

The research team’s simulations of combustion processes for hydrogen-based fuel mixtures showed that SHS-produced porous burners were significantly more efficient than traditional ceramic burners, with efficiency gains ranging from 2.5 to 5 times. Furthermore, the stability of the flame was enhanced due to the unique two-section configuration of the burner, which also simplified the ignition process.

– Numerical modeling, which is being actively developed at TSC SB RAS, plays a critical role in optimizing combustion processes. By adjusting the size and shape of the pores, we can configure the structure of the burners to achieve higher power generating capacities and minimize environmental impact, – concludes Yakovlev.

Looking ahead, TSC SB RAS plans to continue its work on the development of highly efficient porous burners with defined morphologies, produced using SHS and 3D printing technologies, to meet specific industrial requirements and offer tailored solutions for a variety of energy-related challenges.

© TSC SB RAS Press Center