TSC SB RAS researchers studied patterns and mechanisms of the formation of the surface alloys

The results of a comprehensive study conducted at Tomsk Scientific Center SB RAS showed mechanisms of the formation of the W–Zr surface alloys. Based on the obtained results, a scheme was proposed describing the formation of the surface alloys (SAs) upon low-energy high-current electron beam (LEHCEB) processing. The study was published in Vacuum .

– The formation of SAs occurs under non-equilibrium conditions of pulse processing and it is extremely difficult to predict results. To control it and to get results specific to their intended applications we needed more fundamental results in their nature, –explained Evgeniy Yakovlev, researcher of the Laboratory of Advanced Technologies TSC SB RAS.

The following stages of W–Zr SAs formation were established: eutectic melting (melting of two materials taken in a certain concentration, which begins at temperature lower than the known melting point of each of these materials), fragmentation of the tungsten film and sequential dissolution of its individual fragments.

The study of formation of W–Zr SAs included computer simulation and testing. To assess the influence of processing parameters on the formation of W–Zr surface alloy computer simulation of the dynamics of temperature fields has been carried out using the HEATPACK-1.0 software developed at the TSC SB RAS.

The results were then confirmed experimentally. The W–Zr SAs were synthesized using the ‘RITM-SP’ electron-beam machine designed at the Institute high-current electronics SB RAS and the company Microsplav. This machine combined a magnetron sputtering system and a source of low-energy high-current electron beams.

A W film has been preliminary deposited on a Zr substrate. The Zr substrate with the deposited W film was then processed with a LEHCEB. Both chemical and phase compositions of the synthesized surface alloys have been investigated. The obtained results have a crucial role for further optimization of technological maps when it deals with production of protective materials and 3D printing.

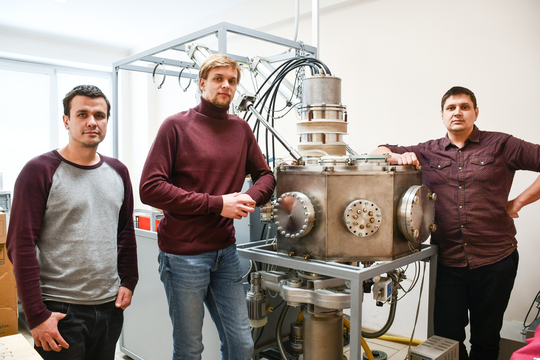

In the photo: Junior researcher at the Laboratory of Advanced Technologies Vsevolod Petrov, Evgeny Pesterev, researcher Evgeny Yakovlev